Composting Operations

Composting is the deliberate decomposition of yard waste or other solid waste, resulting in a humus-like substance beneficial to the soil. Composting also serves as an alternative to landfilling reusable resources.

Design, operation, sampling, record-keeping, and other requirements for regulated and exempt compost facilities are found in Regulation 22. While some facilities are exempt from regulation, they must report to DEQ. Backyard composting is not regulated, but DEQ provides tips and information about backyard composting and vermicomposting.

Compost Permits

- Some yard waste compost facilities are regulated through a general permit.

- Other compost facilities must seek an individual permit.

- The Solid Waste Office collects permit fees on regulated compost facilities.

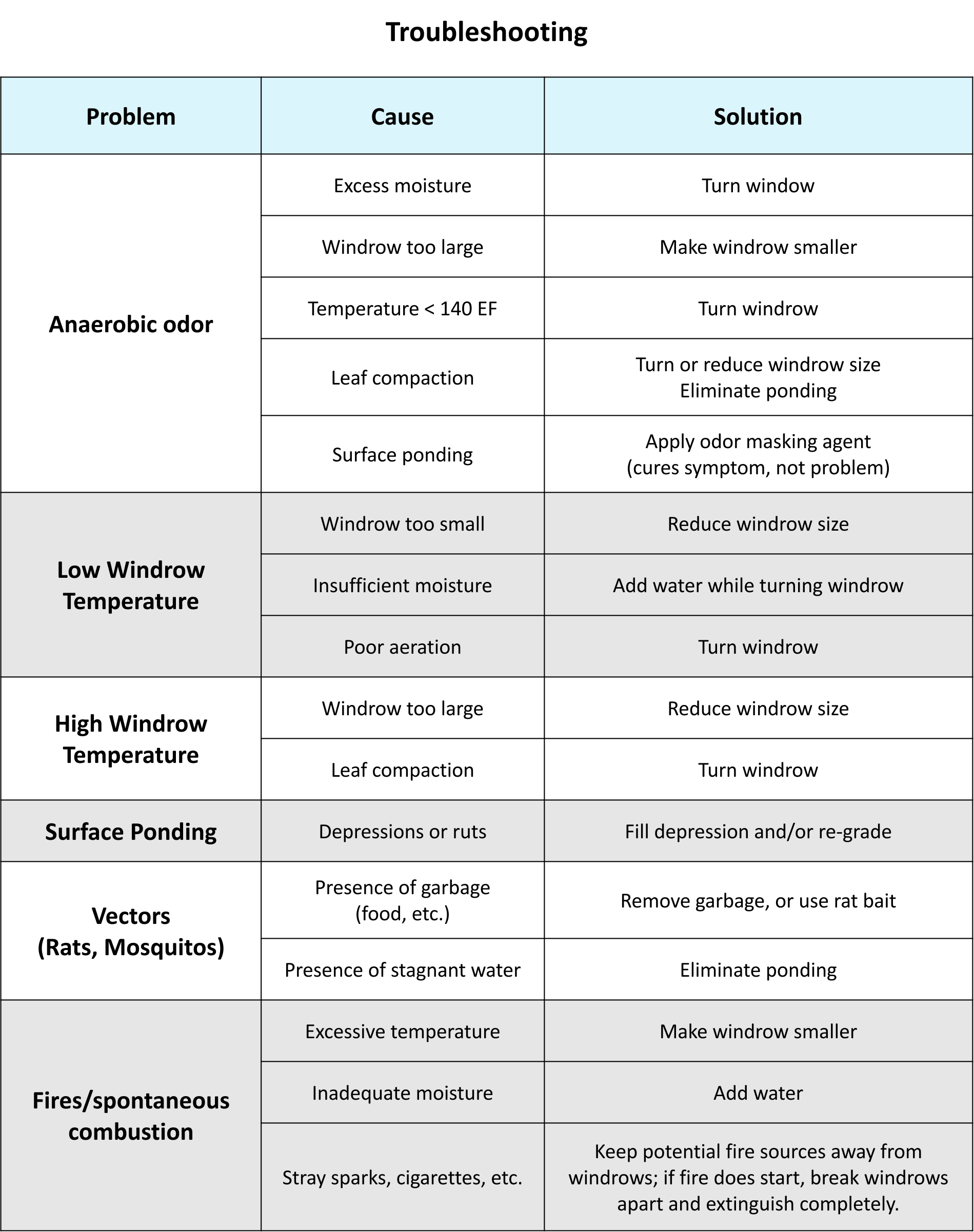

A review of the composting process (section below in this document) may help regulated facilities or even backyard composters produce compost more quickly and without pest or odor problems.

The Composting Process

A basic understanding of the composting process can help produce a high quality product while preventing many common problems. The microorganisms that do the work in composting have a few basic requirements that need to be met. Oxygen, water, and the right food and temperature combine to create a good composting environment.

Composting is an aerobic process, which means it occurs in the presence of oxygen. Oxygen is provided in two ways: (1) by turning the compost, either by front-end loader or a specialized compost turner, and (2) by building a the pile correctly so that surface air can diffuse into the center. When a pile gets too little oxygen, it will go anaerobic, and offensive odors may result.

Microorganisms need water, too. Ideally, the moisture content should be between 40 and 60 percent. If the compost pile is too wet, anaerobic conditions result; if it’s too dry, the decomposition process will slow way down.

Bacteria, fungi, and other microorganisms get their energy from carbon sources, such as leaves, brush, or wood chips. Nitrogen is required for population growth, but excess nitrogen can generate ammonia and other odors and can pollute runoff water. If high nitrogen materials such as grass clippings are used, they must be thoroughly mixed with a carbon source. Surface area is also important in this relationship; for example, the carbon in leaves is much more available than the carbon in large wood chips because leaves have more surface area than wood chips.

As the microorganisms are working away decomposing waste, they generate heat. When the temperature rises above 140°F, the organisms start to die. This can result in drastic population fluctuations and odors. Turning the pile before the temperature reaches 140°F will prevent overheating.

Eventually, the microorganisms will use up most of the readily decomposable waste, and the composting process will slow. Temperatures drop, and the compost takes on a dark, granular texture. At this point, the compost can be placed in large stockpiles to cure, and it will continue to improve until it is ready for use.

Optimal Composting Conditions:

- Oxygen > 10%

- Moisture ˜ 40-60%

- Carbon:Nitrogen 30:1

- Temperature 90° - 140°F

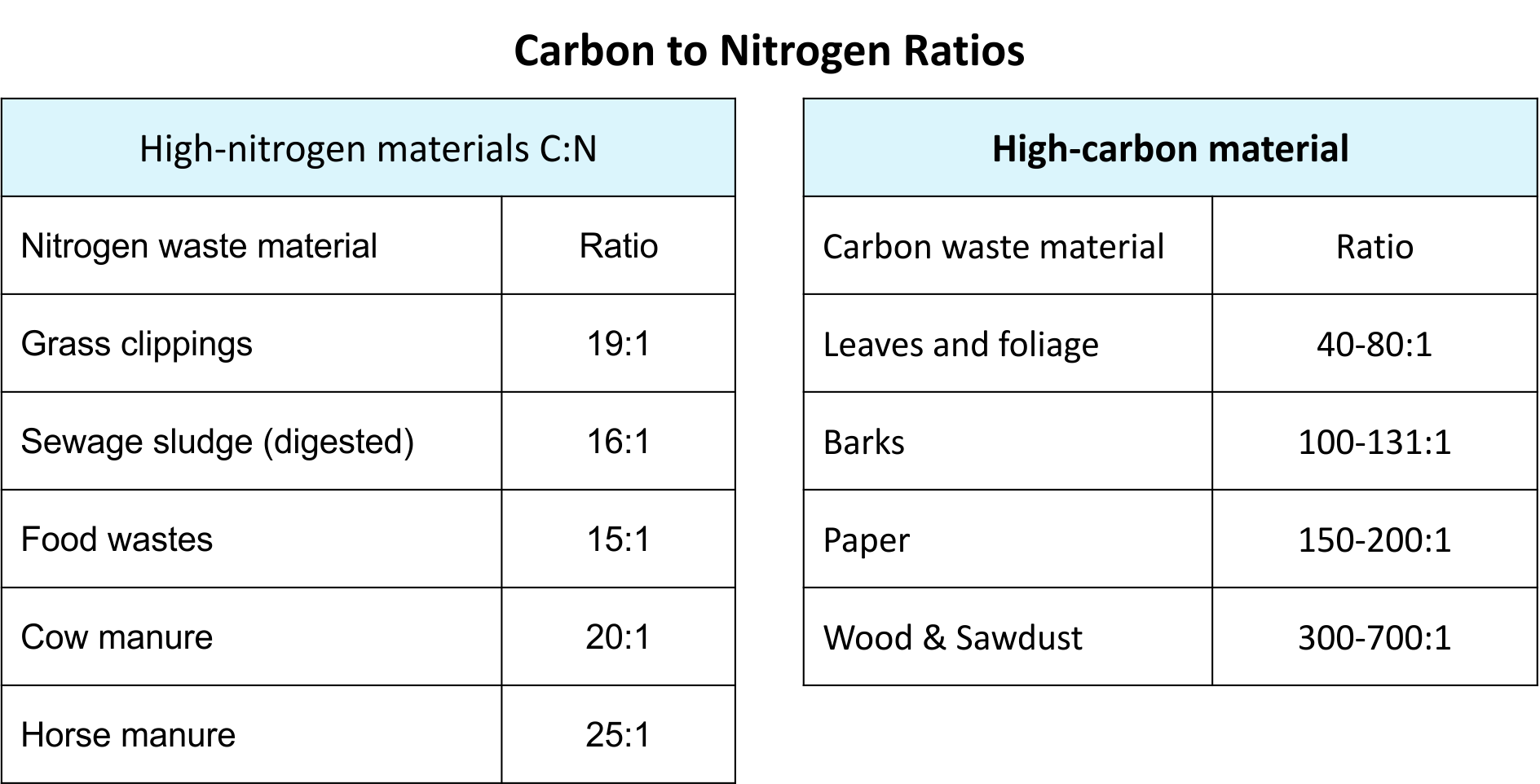

Yard waste consists of a variety of different materials, each having its own characteristics and requirements. When combining different materials such as leaves and grass clippings to make compost, the concept of carbon-to-nitrogen ratios (C:N) is critical. The ideal proportion of these two elements is about 30 parts carbon to 1 part nitrogen by weight.

If carbon and nitrogen are too far out of balance, the microbial system will suffer. When there is little nitrogen, the microbial population will not grow to its optimum size, and composting will slow down. In contrast, too much nitrogen allows rapid microbial growth and accelerates decomposition, but this can create serious odor problems as oxygen is used up and anaerobic conditions occur. In addition, some of this excess nitrogen will be given off as ammonia gas that generates odors while allowing valuable nitrogen to escape. Therefore, materials with a high nitrogen content, such as grass clippings, require more careful management, with adequate aeration or frequent turning as well as thorough blending with a high-carbon waste.

Waste materials can be blended to improve the carbon-nitrogen balance and hasten decomposition. For example, leaves are typically in a ratio of 40-80 units of carbons to 1 unit of nitrogen. Although leaves will compost slowly by themselves, they can benefit from additional nitrogen. Mixing leaves with a high-nitrogen waste, such as grass clippings, manure, or nitrogen fertilizer, will accelerate the decomposition process. Adding one part grass clippings to three parts leaves will balance these nutrients and help composting process in the shortest possible time. The table below presents estimates of the C:N ratios of various composting materials.

Active microorganisms need a moist environment. Ideally, composting materials should be between 40 and 60 percent water. When conditions are too wet, water will fill the pore space needed for air movement, and anaerobic conditions can result. If conditions are too dry, the decomposition rate will slow down.

For leaves, the "squeeze test" is an easy way to gauge moisture content. The leaves should feel damp to the touch, with only a drop or two of water expelled when tightly squeezed in the hand. Leaves are often quite dry when collected in the fall, and water may need to be added by one of the methods discussed below.

Some materials, like grass clippings, may seem dry to the touch but contain a great deal of water in their cell structure. As that structure breaks down, the water is released, turning the grass into a slimy mess. If compost becomes too wet, it may be necessary to add some drier material, such as partially decomposed leaves or wood chips. Coarse material is especially helpful in this situation; it increases the porosity, allowing water to drain out and air to flow in.

The shape of a compost pile has an important effect on moisture content. Scooping out the top of the pile to create a concave shape will maximize water absorption so that rainfall can help replenish the moisture that is lost from the piles as steam. However, if the pile is overly saturated, anaerobic odors and leachate will be produced. In prolonged wet conditions, the pile should be shaped to form a peak that will minimize absorption by shedding water.

Water can be added to the compost pile in various ways. Hosing yard waste as the windrow is turned, or turning it on a rainy day can help get water into the pile. Overhead sprinklers on a concave shaped pile also work well. When water is applied slowly, it is more likely to infiltrate the pile rather than run off the surface. Another method uses a drilled pipe as an injection probe, delivering pressurized water from a water truck to the center of the pile, where it can be readily absorbed. As a rule of thumb, dry leaves initially need about 20 gallons of water for every cubic yard of leaves.

Yard waste composting is an aerobic process; it occurs in the presence of oxygen. The air we breathe is about 21 percent oxygen. Compost organisms can survive with as little as 5 percent oxygen. However, if the oxygen level falls below 10 percent in the large pores, parts of the compost pile can become anaerobic (without oxygen). As anaerobic organisms decompose wastes, they produce methane, an odorless gas, and hydrogen sulfide, which smells like rotten eggs. Because odor complaints are the most common problem at yard waste composting sites, maintaining an adequate oxygen supply is critical.

Air can be supplied by either passive or active means. If pile size remains moderate, fresh air can flow in from the outside of the pile. This passive method includes diffusion and natural convection. Natural convection is driven by a chimney effect: As warm air from the center rises out of the top of the pile, cool fresh air is drawn in at the bottom sides. Leaf compost piles 6 to 8 feet tall and 10 to 15 feet wide will get most of their air from diffusion and natural convection. Materials that decompose more quickly, such as a mixture of grass clippings and leaves, must be placed in smaller piles or oxygen will be depleted. If the pile is too large, oxygen will not penetrate to the center of the pile, resulting in a smelly anaerobic core. Moisture content and the size of composting particles also affect natural convection.

Additionally oxygen can be provided mechanically by turning the compost with a front-end loader or a specialized compost turner. Although the oxygen added by turning lasts only a few hours, turning also loosens the piles so that air can flow more easily by diffusion and natural convection. In some compost operations additional oxygen is supplied by a system of blowers and perforated pipes. These forced aeration systems are somewhat more expensive, but the cost may be justified if grass clippings are causing persistent odor problems or if the yard waste is being composted with other materials such as sludge.

As organisms decompose waste, they generate heat. Decomposition is most rapid when the temperature is between 90E and 140EF (32E-60EC). Below 90EF (32EC), the process slows considerably, while above 140EF (60EC) most microorganisms cannot survive. Compost pile temperature depends on how the heat produced by microorganisms is offset by the heat lost through aeration or surface cooling. During periods of extremely cold weather, piles may need to be larger than usual to minimize surface heat loss: When composting high-nitrogen wastes, like grass clippings in the summer, smaller piles and frequent turning are needed both to provide oxygen and to release excess heat.

After an initial high temperature period (of a few days to several weeks), compost pile temperatures will gradually drop. Turning the compost rejuvenates the oxygen supply and exposes new surfaces to decomposition, causing temperatures to rise. If temperatures rise above 160EF (21EC), the compost can sterilize itself, killing off the beneficial microorganisms. Extremely high temperatures can also start the chemical process of spontaneous combustion, which might lead to the outbreak of a fire. Turning the compost when temperatures exceed 140EF (60EC) can prevent both of these potential problems.

When the temperature drops below 70EF (21EC), the composting process is nearly complete. It is also possible that imbalances of oxygen or moisture are causing the pile to cool. If the compost is properly moist and turning does not cause the temperature to rise, the compost is probably finished.

Temperature monitoring is very important for managing the compost process. By measuring temperatures regularly, you can tell how fast material is composting and whether there are hot or cold spots in the pile. Turning the compost whenever temperatures get above or below the optimum range will help produce high quality compost in the shortest possible time.

The first stages of composting are in many ways the most important, and proper windrow construction is the key to getting the process off to a good start. The two aspects of windrow building are (1) mixing materials and (2) forming and shaping the windrow. Both are discussed below.

If several different types of waste are going to be composted together, they must first be thoroughly blended. Mixing is required to balance the carbon and nitrogen ratio and distribute moisture throughout the pile, and also to ensure an even distribution of large pores so that oxygen can move freely. If grass clippings or other high-nitrogen materials are being composted, this blending process is particularly critical. Mixing can be accomplished with a front-end loader, although other equipment such as tub grinders or specialized windrow turning machines are commonly used when mixing grass clippings, which tend to mat together.

The size and shape of the windrow are designed to allow oxygen to flow throughout the pile while maintaining temperatures in the proper range. If windrows are too large, oxygen cannot penetrate to the center. If they are too small, they will not heat up properly. The optimum size varies both with the type of material and with the time of year. Windrows of autumn leaves should typically be about 8 feet tall and 16 feet wide at the base but may be built as high as 10 feet in midwinter. A windrow of grass clippings mixed with leaves will need to be considerably smaller, usually about 5 feet high and 10 feet wide. These sizes are approximate and may need to be adjusted somewhat.

While constructing the windrows, try to avoid driving on and compacting the yard waste. The windrows can be built by lifting the material with the buck of a front-end loader and letting it cascade down to form a loose pile. The sides of the windrow can be as steep as the material will naturally pile up, which typically leads to a windrow about twice as wide as it is high. Windrows can be as long as is convenient for the site, up to several hundred feet in length.

There are two goals to keep in mind when turning a compost windrow. First, move material from the outside of the pile to the middle where it can decompose more quickly. Second, loosen and fluff the material so that it will be more porous and air can move freely. Specialized windrow turners are designed to accomplish both of these goals. A front-end loader can do the job as well. First flip the top of the windrow over just beyond the existing windrow. Second, take the compost from the bottom of the old windrow and place it on top of the new windrow. Let the compost cascade out of the loader, to keep it as loose as possible.

Turning frequency should normally be based on temperature and should occur whenever temperatures exceed 140EF or drop below 90EF. If the compost is staying in this range on its own, regular turning can accelerate decomposition by mixing the material and exposing new surfaces. Leaves may need to be turned only a few times a year but will benefit from turning as often as every two weeks. On the other hand, grass clippings, even when properly nixed with leaves, may initially need turning once or twice a day. As decomposition proceeds and the compost becomes more stable, frequent turning becomes less important.

If the compost has become anaerobic and smells, turning will temporarily add oxygen but may also stink up the neighborhood. Schedule compost turnings to minimize any negative impacts by considering such factors as wind direction, when people are home, and whether they are likely to be outside or have their windows open. Before turning, try to determine the root of the problem, such as too much water, too much nitrogen, or the pile’s being too large. Remedial action can then be taken as the compost is being turned.

Of all the materials in the solid waste stream, woody yard wastes are perhaps the easiest to recycle. A variety of shredding and grinding machines will transform brush and woody waste into chips that are immediately marketable or can be easily stored. And markets for the chip products, either as mulch or fuel, are more stable than the markets for many other recyclable materials.

There are three general types of chipping equipment that might be appropriate for a yard waste management facility: mobile chippers, tub grinders, and stationary hammer mills. For small quantities of woody waste, a small mobile chipper such as used by utility companies and arborists may be the most cost-effective. Since many public works departments already own such a unit, it may be possible for a yard waste management facility to share existing equipment. The primary limitations of these smaller units are their lower throughput rates and their limited capacity for large pieces of woody waste.

Tub grinders have a large-diameter rotating tub that feeds a hammer mill. These units are semi-portable and can usually handle woody materials up to railroad tie size or larger. Stationary hammer mills differ from tub grinders in that they are fed by conveyor belts. They are available in a variety of capacities to handle almost any amount and type of waste.

Tub grinders and stationary hammer mills can process large volumes of material and can be connected to screens and magnetic separators to produce a high quality end product. Both require a considerable capital investment, and maintenance of the hammers can be both frequent and expensive. Stumps, plastic bags, and dirt in the incoming waste will increase these maintenance requirements. Specially hardened steel placed on the critical wear surfaces can significantly extend the service time of the hammers.

The various market outlets for wood chips have somewhat different product requirement. Chip size, moisture, and age can be managed to suit the users. Mulch users such as landscapers and parks are primarily concerned about size, shape, and color. Most large chipping and grinding equipment can produce several different chip sizes, usually by changing a replaceable screen that prevents larger pieces from leaving the grinding chamber. A second stage of screening may also be used to separate the smallest chips and fine material for blending with compost or soil. If mulch users prefer a uniform brown product, aging the chips for a few weeks will turn any green foliage brown.

If the chips are going to be marketed as fuel or as a carbon source for sludge composting, they need to be kept as dry as possible. Covered storage areas may be required if the chips are stockpiled. When storing large quantities of wood chips, caution should be exercised to help prevent fire.

Attention to health and safety concerns can minimize most occupational risks at yard waste recycling facilities. While composting and chipping are not inherently dangerous activities, precautions are necessary to protect against injury and possible illness. Safety concerns relate primarily to equipment. If front-end loaders or other standard heavy equipment is used, ear protection and other normal safety precautions apply. Composting and chipping equipment have additional dangers. These typically contain powerful mixing flails, knives, or hammers that rotate at high rates of speed and should therefore be well-shielded from human contact. Additional precautions must be followed when specialized windrow-turning equipment is used. As the flails rotate through the compost windrow, they will eject foreign matter from the windrow. Stones and other foreign objects can become dangerous projectiles and can be thrown a long distance in front of or behind the turning equipment. Equipment operators must ensure safe clearances on all sides of the operating machinery.

When stockpiling chips or compost, be sure to plan for the possibility of fires. Dry chips and leaves are particularly susceptible to stray sparks from cigarettes or welding equipment. Fires are rarely a problem in outdoor composting operations. Because the inside of the windrows should be damp, compost normally burns poorly. However, if the material does dry out and gets too hot, combustion can occur. Organic material can ignite spontaneously at moisture contents between 25 and 45 percent. This sometimes happens to stored hay or silage and can happen to compost as well. First, however, the material has to heat to over 200EF (92EC), which typically requires a pile over 12 feet high. Keeping the windrows under 10 feet high and turning the compost when temperatures exceed 140EF (60EC) are good compost management practices that also provide protection.

In the event of fire, whether by spontaneous combustion or vandalism, the site must have delivery capacity and an adequate water supply. Maintain clear aisles between windrows to provide easy access in case of fire.

Health concerns relating to compost are dependent on both the individual and the material being composted. While few human pathogenic organisms are found in vegetative wastes or farm animal manures, normal sanitary measures (i.e., washing hands before touching food, eyes, etc.) are important. While many compost operations have run smoothly for years without unusual health or safety problems, there are some unique concerns in composting that workers should be aware of. By understanding these concerns, it will be easier to recognize problems early and seek an appropriate remedy before serious compilations develop.

Just as individuals vary in their resistance to disease, a few individuals may be particularly sensitive to some of the organisms in compost. The high populations of many different species of molds and fungi in an active compost process can cause allergic reactions in sensitive individuals, though most experience no adverse reaction. Conditions that may predispose individuals to infection or an allergic response include a weakened immune system, allergies, asthma, some medications such as antibiotics and adrenal cortical hormones, or a punctured eardrum. Workers with these conditions should not normally be assigned to a composting operation.

To minimize the risk of infection, Occupational Safety and Health Administration (OSHA)-approved dust masks or respirators should be worn under dry and dusty conditions, especially when the compost is being turned. If, following these precautions, workers still develop an infection or have an allergic reaction to compost, they should consult a medical professional.

Municipal Yard Waste Composting

Municipal yard waste composting projects range from small part-time operations handling a few hundred cubic yards a year, to huge facilities processing tens of thousands of yards with several full-time employees. Operators who understand the basics of the composting process can help insure the program’s success, whatever the scale.